5 Apr 2021

SMA actuator control without a position sensor

VCM-based AF and OIS camera module actuators usually require a position sensor such as a Hall Effect sensor to achieve accurate control of the actuator. Using CML’s patented Shape Memory Alloy (SMA) technology, we are unique in that the SMA acts as both actuator and sensor, resulting in a single-piece motor the size of a human hair that can be controlled to the accuracy of the wavelength of light. No position sensor is required, saving space and cost!

In this article, Bronwen Derry, Principal Development Engineer at CML, explains how we control an SMA actuator without a position sensor.

SMA wire contracts significantly when heated, creating large forces and motion with respect to its size. Therefore it is well suited for compact applications requiring strong and precise actuation.

For high accuracy applications, most motion control systems use feedback control. This involves taking measurements of the position with a sensor and making a calculated adjustment to any position error using the actuator. In conventional systems this requires separate components to act as a sensor e.g. a Hall sensor and magnet, which are used in conjunction with a VCM (Voice Coil Motor) actuator.

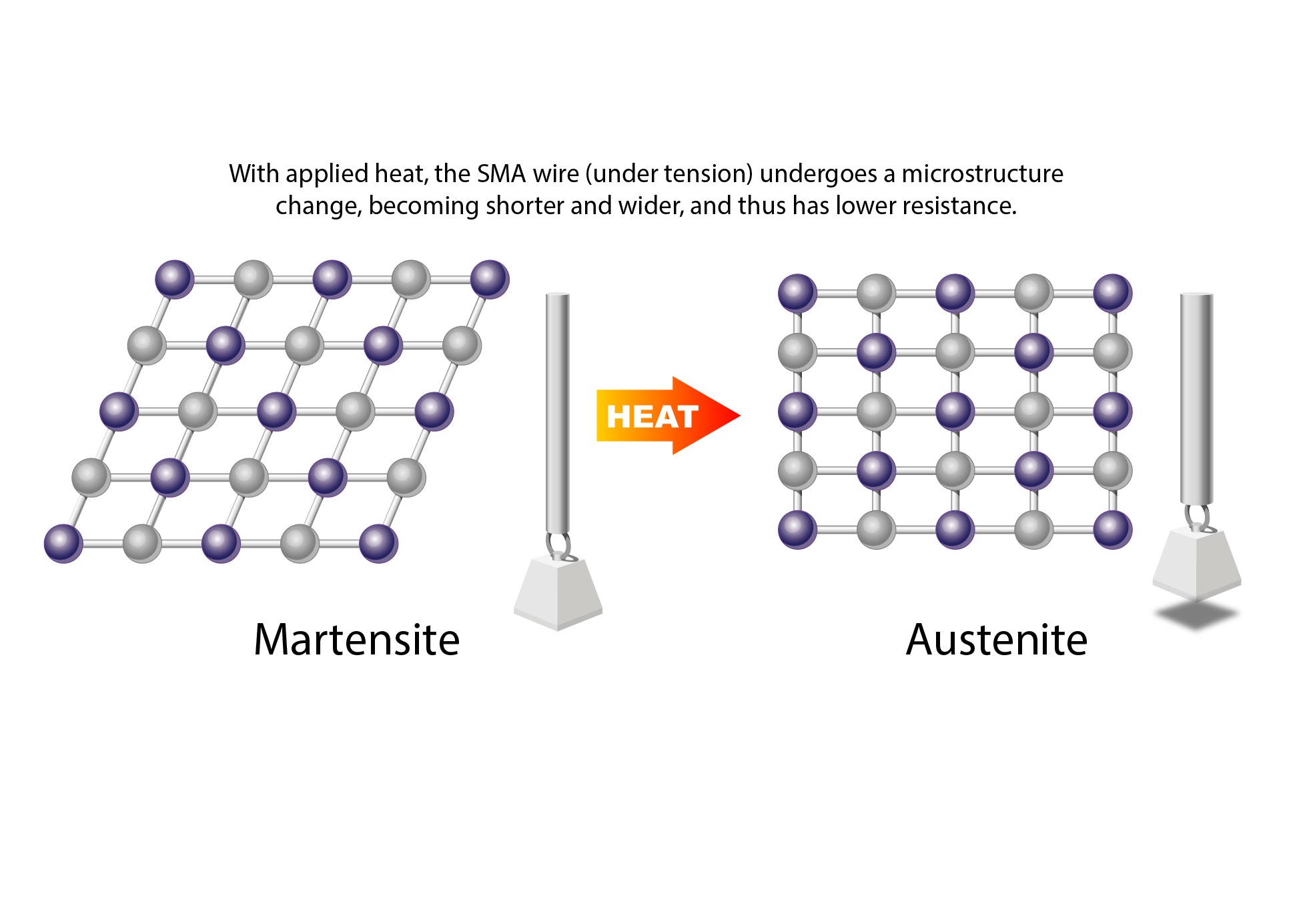

SMA undergoes a microstructure change when heat is applied, and this change in crystal structure drives the change in shape, which provides the motion. However, this change in geometry also results in key changes in the wire resistance, that can be used in proxy for a position sensor. Consider the Electrical Resistivity Equation:

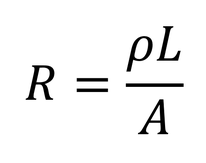

Consider the Electrical Resistivity Equation:

where R is the resistance, L is the length, A is the cross-sectional area, and ρ (Greek letter “rho”) is the Resistivity.

When the wire is cold, it is long and narrow. When the wire is hot, it shrinks, becoming shorter and wider. Both effects drive the resistance down. Therefore, we have a known relationship between wire resistance and wire length and we can monitor the wire resistance to calculate our position.

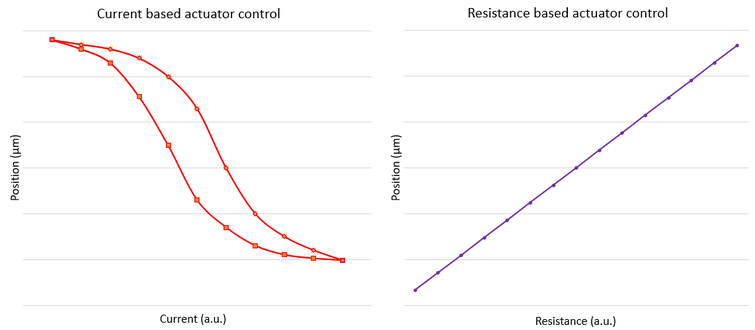

VCM control with current is well known to be hysteretic, and the native motion vs wire temperature (or current) for SMA is also very non-linear and hysteretic and therefore can be difficult to control. However, CML’s resistance control gives a linear response with respect to position, allowing for accurate control. CML is the first company in the world to precisely control the contraction of SMA wire in this way.

CML’s SMA platform technology enables the most compact form factor for any actuator application where a high level of precision and force is required. CML’s multidisciplinary team are building tailored system solutions for smartphone camera AF and OIS, 3D sensing, augmented reality and haptics.

For more details about Cambridge Mechatronics and our SMA technology platform, please get in touch.