23 Sep 2024

Increasing image stabilisation by 50% with Stroke Extension technology from Cambridge Mechatronics

By Stefan Hansen (Marketing Communications Manager), in conversation with Dr. Jamie Rogers (Senior Systems Engineer)

Optical Image Stabilisation (OIS) is crucial for achieving high-quality videos and images in smartphone cameras. The SMA Lens shift AF+OIS design from Cambridge Mechatronics Ltd (CML) has successfully shipped into many handsets, including into the highly competitive mid-market segment. As the industry demands continuous product improvements, CML has developed an innovative solution to significantly enhance the OIS stroke capability. This article presents the Stroke Extension technology and explains how this new capability improves OIS performance by increasing the compensation angle by 50% or more.

8-wire technology and 6 degrees of freedom

CML’s Shape Memory Alloy (SMA) 8-wire technology forms the backbone of the integrated Lens Shift AF+OIS system. Traditional OIS products contain two actuators, one of which provides 2-axes of translational shift movements of the lens or image sensor to stabilise images and the other provides one axis of motion for autofocus (AF). In contrast, CML’s 8-wire technology is able to position the lens across all six degrees of freedom (DoF). This allows for movement not only in the X, Y, and Z directions for OIS and AF functionality, but also rotational movements around these axes.

One benefit of controlling the lens across six degrees of freedom is that it opens new creative opportunities for photographers. Features like multipoint focus and tilt-shift effects may become accessible, allowing users to experiment with depth of field and perspective, currently limited to much more expensive, professional-grade cameras and lenses.

The concept of Stroke Extension

To date, CML’s Lens Shift AF+OIS actuator design and control algorithm provided a compensation angle of around ±1 degree. Stroke Extension is principally a control feature provided by CML’s driver chip (CM824) that increases the lens's range of motion without mechanical changes to the fundamental actuator design.

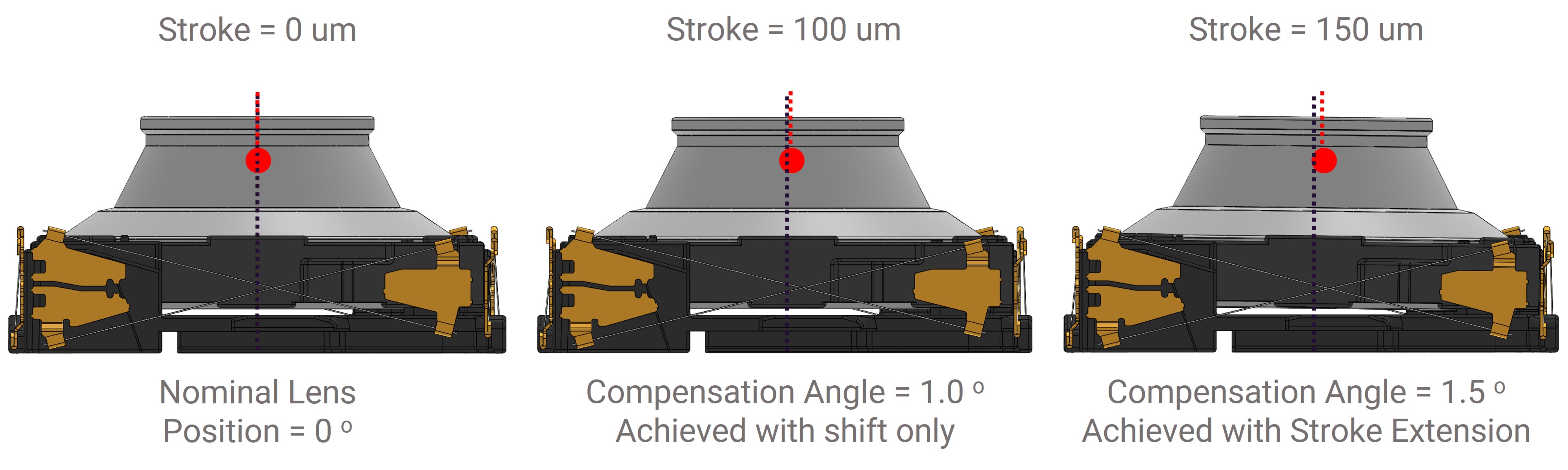

CML’s Stroke Extension is based on the fact that OIS is delivered by the shift of the top of the lens and not the shift of the centre of the lens. This means that by adjusting the tilt, the top of the lens can be moved further, expanding the compensation angle from ±1 degree to ±1.5 degrees or more, as shown in Figure 1. This 50% improvement enables the camera to correct for more significant shakes, resulting in clearer images, even in challenging conditions such as low light.

Figure 1: This to-scale illustration represents the additional 50 µm of translational motion of the lens centre enabled by 0.67 ° of lens tilt, increasing the compensation angle from ±1.0 ° to ±1.5 ° for a lens with an effective focal length (EFL) of 6.67mm.

The enhancement is achieved with minimal changes to existing hardware needed to accommodate the added tilt, focusing primarily on updates to CML’s advanced SMA control algorithms.

Improvements in optical stabilisation

CML’s tests show that when compared with the standard OIS shift configuration, the enhanced system delivers better stabilisation particularly in scenarios involving larger shake angles. Extended OIS stroke capability means less image blur in photos and videos during many everyday use cases.

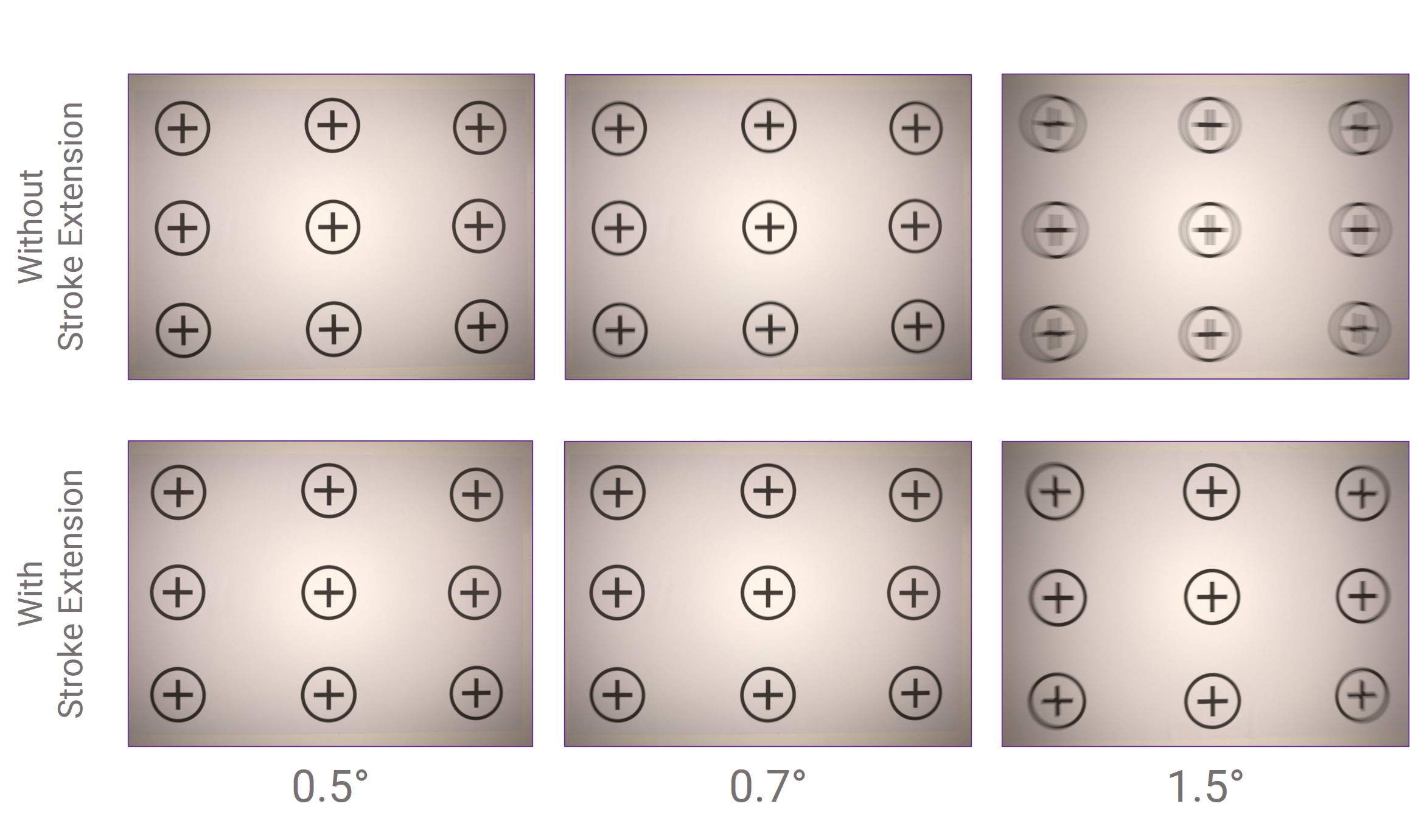

Examples of a shake test comparison with the standard Lens Shift AF+OIS demonstrate the benefits of Stroke Extension clearly, as shown in Figure 2. In these tests, cameras are mounted to a shaking rig and a target is placed at a distance of 40 cm. The tests show a comparison of how stable the images appear at varying degrees of handset shake.  Figure 2: The Stroke Extension camera performs best at 1.5 ° shake, showing significantly reduced blur compared to the basic actuator control. The test was run at 6 Hz shake frequency.

Figure 2: The Stroke Extension camera performs best at 1.5 ° shake, showing significantly reduced blur compared to the basic actuator control. The test was run at 6 Hz shake frequency.

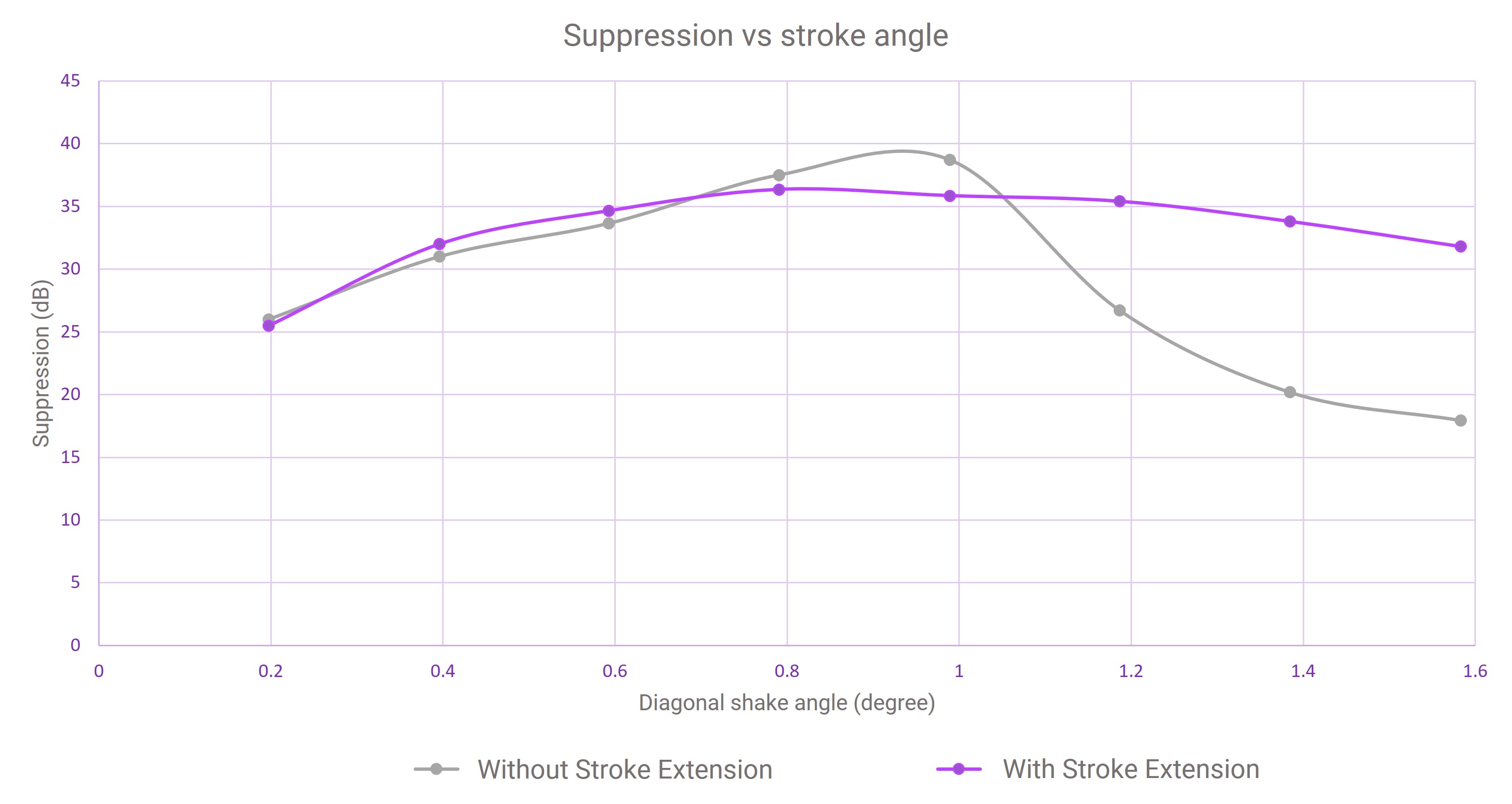

Quantifying the results from Figure 2, the graphs in Figure 3 show the suppression in dB units comparing Lens Shift AF+OIS with and without Stroke Extension. The additional stroke capability means that OIS with Stroke Extension can deliver levels of suppression for substantially higher stroke/compensation angles than before.

Figure 3: Comparison of Lens Shift AF+OIS with standard OIS vs Stroke Extension OIS – suppression and stroke angle. Object distance is 40 cm and a shake frequency is 6 Hz is used.

Figure 3: Comparison of Lens Shift AF+OIS with standard OIS vs Stroke Extension OIS – suppression and stroke angle. Object distance is 40 cm and a shake frequency is 6 Hz is used.

Benefits for video

In real-world situations, the Stroke Extension capability ensures that the OIS system can better stabilise for video and image capture. The demonstration videos in Figure 4 below have been captured without any accompanying Electronic Image Stabilisation (EIS) switched on.

Figure 4: Video comparison of standard OIS and OIS with Stoke Extension

Bringing Stroke Extension to the market

CML’s Stroke Extension feature has been tested extensively on existing SMA Lens Shift AF+OIS systems based on 8-wire technology, with impressive results.

For smartphone manufacturers, this means that Stroke Extension can be incorporated into new devices with minimal disruption to existing production processes. The result is a significant enhancement in SMA OIS performance, offering a very competitive solution for the mid-range smartphone market segment.

Looking ahead with CML

As smartphone cameras continue to advance, features like Stroke Extension will play an important role in shaping the future of mobile photography. By extending the stabilisation range and offering new creative tools for photographers, CML has shown its ability to develop innovative solutions to continue to enhance the capabilities of tomorrow’s smartphone camera.

Stroke Extension represents a major improvement in SMA OIS technology, enabled by the development of new control features available on CML’s controller IC, CM824. By enhancing the ability to stabilise images across a wider range of movements, CML is providing users with the tools needed to capture stunning photos and film in any situation. With the adoption of this technology, the gap between smartphone and professional photography continues to narrow.

Cambridge Mechatronics is a world-leading developer of mechanical, optical, electrical, silicon, and software designs for system-level solutions using its Shape Memory Alloy (SMA) platform technology. ACTUATOR SOLUTIONS based on SMA wire (thin as hair) can be controlled to submicron accuracy. These actuators are particularly suited to applications requiring high precision and force levels, in a fast, compact, and lightweight design.

For more details about SMA technology and Cambridge Mechatronics, please GET IN TOUCH.